5 Ways to Add Engineering Tolerances in Excel Cells

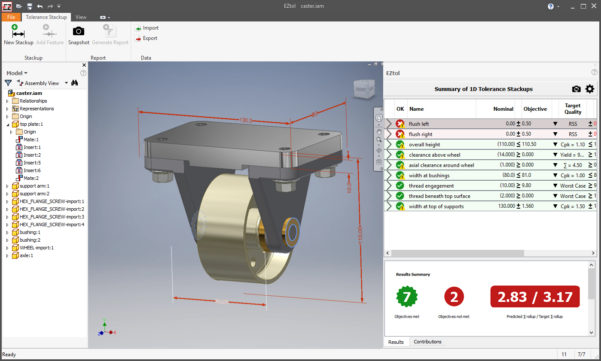

In the realm of engineering, precision is everything. Whether you're designing mechanical parts, creating prototypes, or analyzing data, accuracy down to the last detail is critical. Microsoft Excel, despite not being an engineering software per se, provides a robust platform for managing engineering tolerances thanks to its versatile data manipulation capabilities. In this detailed guide, we'll explore five different methods to add engineering tolerances in Excel cells, ensuring your specifications are both precise and clear.

1. Using Cell Formatting

One of the simplest ways to include tolerances in Excel is by leveraging cell formatting. This method is particularly useful when you want to visually separate the nominal value from the tolerance.

- Select the Cell: Click on the cell where you want to show the dimension with tolerance.

- Enter Data: Type the nominal value followed by the plus/minus symbol and the tolerance value, e.g., “50±0.05”.

- Apply Formatting: Right-click, choose ‘Format Cells’, and under the ‘Number’ tab, select ‘Custom’. Here, you can create your own format that visually separates the nominal value from the tolerance.

⚙️ Note: Ensure the tolerance is kept in the same cell as the nominal value for consistency and clarity.

2. Adding an Error Bar

Error bars in Excel are typically used in charts to represent the variability of data, but they can be adapted for engineering tolerances on drawings or tables.

- Chart Creation: Insert a chart with your data. Typically, this would be a scatter or line chart.

- Error Bars: With the chart selected, click on ‘Add Chart Element’, then ‘Error Bars’, and choose ‘More Error Bars Options’.

- Set Error Bars: In the formatting pane, select ‘Both’, enter the tolerance values for ‘Positive Error Value’ and ‘Negative Error Value’, and set the ‘End Style’ to cap.

This approach visually communicates the tolerance range, making it clear where the upper and lower limits lie without cluttering the data table.

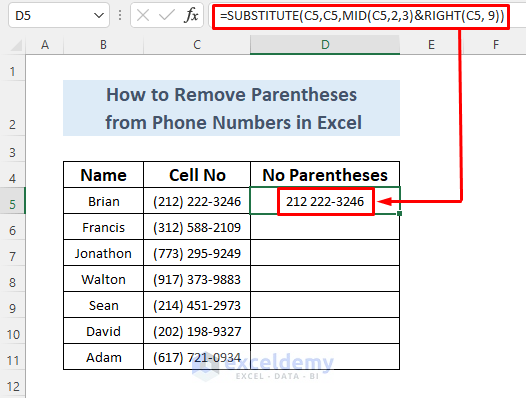

3. Utilizing Excel Formulas

Excel’s formula capabilities can help automate tolerance calculations and representation:

- Nominal Value: Enter the nominal value in one cell (e.g., A1).

- Upper Tolerance: Use a formula in another cell (e.g., B1) to calculate the upper limit:

=A1+C1, where C1 contains the tolerance value. - Lower Tolerance: Similarly, calculate the lower limit in cell C1:

=A1-C1. - Combined Display: Concatenate these values in a display-friendly format using functions like

=TEXT(A1,“0.00”) & “+” & TEXT(C1,“0.00”)or=TEXT(A1,“0.00”) & “±” & TEXT(C1,“0.00”).

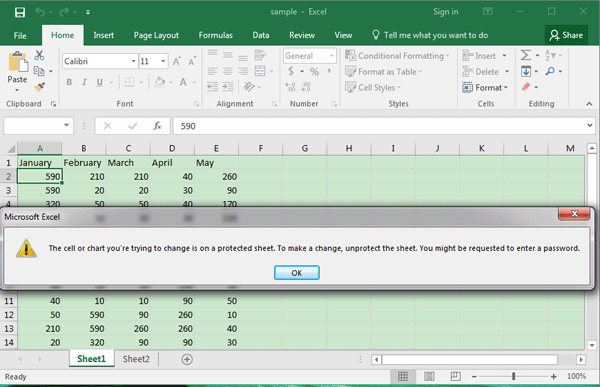

4. Using Conditional Formatting

Conditional formatting can highlight cells that exceed tolerance limits or fall out of the acceptable range:

- Select Data Range: Highlight the cells or range of cells you want to apply formatting to.

- Conditional Formatting: Go to ‘Home’ > ‘Conditional Formatting’, and set a rule to change the cell color if the value deviates from the nominal value by more than the tolerance.

- Set Conditions: Use formulas like

=AND(A1>(B1+C1),A1<(B1-C1))to check if the value is within tolerance.

This visual cue can be immensely helpful during data review, instantly showing where tolerances are violated.

5. Utilizing Tables

Tables provide an organized way to manage and present engineering data with tolerances:

| Component | Nominal Dimension | Tolerance | Upper Limit | Lower Limit |

|---|---|---|---|---|

| Part A | 50 | ±0.05 | =A2+B2 | =A2-B2 |

| Part B | 100 | ±0.1 | =A3+B3 | =A3-B3 |

Using tables streamlines data input, calculations, and readability, making it easier to manage large datasets.

In conclusion, Excel offers several methods to handle engineering tolerances, catering to different project needs and preferences. From simple formatting to advanced formula-based techniques, each approach provides unique benefits. Whether you’re interested in visualizing tolerance ranges or automating tolerance calculations, Excel’s flexibility ensures your engineering specifications remain accurate, readable, and ready for analysis.

What are engineering tolerances?

+Engineering tolerances specify the acceptable limits of variation in the size or other physical characteristics of a product or its components. These limits ensure that the part can still function within its intended design specifications despite small variations in manufacturing.

Why is it important to use tolerances in engineering?

+Tolerances are crucial in engineering to account for manufacturing imperfections, variations in materials, and environmental factors. They ensure that parts can be interchangeable and still meet the functional requirements, reducing defects and improving assembly efficiency.

Can these methods work in other spreadsheet software?

+While the specifics might differ, most modern spreadsheet software supports similar formatting, formulas, and conditional formatting features, allowing these techniques to be adapted for use in programs like Google Sheets or LibreOffice Calc.

How can I ensure my tolerances are correctly interpreted?

+Clearly label your tolerances in your Excel workbook, use appropriate formatting to distinguish them from nominal values, and always double-check calculations and formatting with a colleague or supervisor to ensure accuracy and readability.

Related Terms:

- Download Tolerance calculator excel

- Excel formula for plus minus

- Excel threshold formula